Cutting the Ply

Cutting the Ply | |

|

I skipped this bit. This meant that I didn't have to transfer dimensions from the plans to the ply,

curve a batten along the markings on the ply, draw a line along the batten, cut along the line with a jigsaw

and finally plane up to the line.

|

|

|

It sounds easy but there is 364ft of marking, cutting and planing just to make the planks.

I could make a mistake at this stage and not notice until months later when the boat wasn't boat shaped.

|

|

|

Instead of doing all this I got Jordan Boats to cut the ply which they did with a minimum wastage saving me a significant part of the cost of having the ply cut.

This saved a lot work, guaranteed that everything was the right shape (always a good start) and left me to get on with the really interesting bit - putting the boat together.

|

|

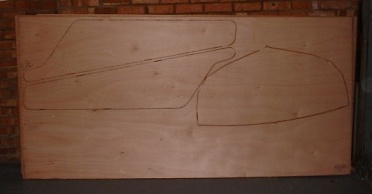

| The ply comes with all the parts cut out but still held in place by small tabs of plywood - a giant Airfix kit. These tabs have to be cut through and planed off. Jordan Boats also provide a diagram showing the layout of the parts on each sheet. The planks look very similar to one another. The order of work is to identify each part on each sheet of ply from the diagram and write an identifying label on it and not to enthusiastically cut out everything and then wonder which bit is which. |